We ask you, urgently: don't scroll past this

Dear readers, Catholic Online was de-platformed by Shopify for our pro-life beliefs. They shut down our Catholic Online, Catholic Online School, Prayer Candles, and Catholic Online Learning Resources essential faith tools serving over 1.4 million students and millions of families worldwide. Our founders, now in their 70's, just gave their entire life savings to protect this mission. But fewer than 2% of readers donate. If everyone gave just $5, the cost of a coffee, we could rebuild stronger and keep Catholic education free for all. Stand with us in faith. Thank you.Help Now >

Could DWR forfeit the FEMA & CA customer's $500 million in Spillway repair funding? Will DWR be found Legally Liable in deep void filling? Hid deep voiding from FERC? Who will pay the bills?

FREE Catholic Classes

Did DWR hide serious deep voiding problems under the Main Spillway from FERC? Searching 20 years in FERC's database of 3,525 Oroville tied documents finds no DWR notification to FERC of serious deep voiding problems? If DWR withheld a Category 1 severe failure problem from FERC, does this risk forfeiture of FEMA funding? What about the CA customers in their expected 25% in repair costs? Will this end up in the courts?

LOS ANGELES, CA (California Network) - California Department of Water Resources (DWR) may soon be facing another crisis, except this crisis may be from the risk of loss or forfeiture of the spillway repair reimbursement from FEMA and DWR's Water Customers. The key to this crisis may be from the withholding of catastrophic rated Category 1 Failure mode information from the Federal Energy Regulatory Commission (FERC). FERC is charged with the oversight of safety of large public dams in the US. FEMA's decision to allow "disaster" event status for Oroville, in granting funding aid, likely rested on the belief that this event occurred from an "unexpected" condition, even though the spillway was operating at 18% of its full design rated capacity when it failed [18]. FERC undoubtedly believed that this spillway blowout failure was an "unexpected event", as the Regional Engineer of FERC's Division of Dam Safety and Inspections, Mr. Blackett, described in a recent American Society of Civil Engineers (ASCE) conference in Sacramento May 21, 2017 [5]. Thus, FEMA's decision may have been attributed to information from FERC - in deciding the "disaster status" - although the spillway was operating well under its design rating when it failed.

However the funding reimbursement issue could take a sharp and unexpected turn when looking deeper into new discoveries. FERC expects a high level of expertise and competence when interfacing with dam owners, such as DWR, to facilitate the task of assuring the maximum level of operational safety of a dam. A primary FERC operational safety assurance process is called the Dam Safety Performance Monitoring Program (DSPMP). The tools to this periodic proactive exercise are physical dam Inspections and Potential Failure Mode Assessments (PFMA's) - which are performed by Independent Consultants [6]. As a dam owner, DWR is required to extensively contribute to the formation of a PFM [10] such as probability of a failure causation, the mechanisms involved, and the ability to detect or mitigate the development of a failure mode. Dam owners are ultimately responsible for public safety and are obliged to engage FERC if any sudden or new PFM is discovered.

What would happen if a Dam Owner does not reveal a serious Potential Failure Mode? Or, what if the Dam Owner mistakenly believed that the PFM was not considered a threat? In either case, Civil Law and Civil Court does not distinguish between "incompetence" or "engineering ethics". The Law in Liability applies a "Standard of Care" requirement for engineers to be competent in their field of expertise to their profession[8][9]. All dimensions of Potential Failure Modes to the Main Spillway are the responsibility of the collective engineering expertise utilized by a Dam Owner, including outside consultants. In this case it would be DWR's Division of Engineering, DWR's Division of Operations and Maintenance, and California Division of Safety of Dams (DSOD).

What Serious Failure Threat could be Hidden from FERC & Inspections? Something not visible. Both FERC and DSOD Inspectors perform visual inspections on the main spillway surface concrete. DSOD Inspectors seemingly do not perform any subsurface testing or "soundings" of the slab concrete. DWR's Division of Operations and Maintenance (O&M) perform the "soundings" for subsurface conditions under the spillway chute concrete. Thus, the only noted DSOD Inspector's commentary on "drummy patches" discovered on the main spillway was from other prior activities and not from the Inspection [11]. Another DSOD Inspection report noted "chains" being used for soundings on the spillway concrete, but noted that the activity was "recently sounded" rather than noted from the Inspection itself [12]. All of the available DSOD Inspection reports dating to 1998 consistently report of only visual inspections of the spillway concrete.

So why is the focus on "Inspections" when DSOD Inspectors do not perform any subsurface testing under the main spillway concrete? At the same May 21, 2017 Sacramento ASCE conference, DWR's acting deputy director, Mark Anderson, stated, "In 2014, an inspection actually dismissed the plausibility of a failure of the concrete chute" [5]. Yet Mr. Blackett, referred to the array of state and federal "inspectors" who had "missed signs" of the pending catastrophic failure of the main spillway. Again the focus is on "inspections" and "inspectors". What is missing from this discussion is information that could soon change the "narrative" from "inspections" to evidence that is hiding unseen beneath the spillway - to where typical inspections will not detect. This evidence is so significant, that it would be very difficult to substantiate that this was not "unforeseen".

The "narrative" may be unraveling -

On March 10, 2017, an "accidental" release of the first Independent Board of Consultants (BOC) memorandum provided the first public revelation of DWR conducting "void filling" under Oroville's failed Main Spillway [1]. The group of experts which form the BOC, noted, "It seems likely that piping of foundation material beneath the chute slab may be responsible for the voids that have been found and repaired in the past.". The BOC detailed an erosion process from pressurized water flow (piping) that eroded the highly weathered rock foundation underneath the spillway concrete slabs, thus forming cavities or voids that were discovered and "repaired in the past". Who found the voids? None of the DSOD Inspection reports note a "finding of voids" except for the single 2000 DSOD report note that "Mr Wolf said" to the Inspector of "drummy patches" (void detection by acoustic stimulation) on the main spillway were found [11].

Who repaired the voids? Was FERC notified? A single letter was found out of 3,525 filings of FERC/DWR communications using a database search where the word "void" (voiding, voids, etc) was identified [3]. Yet in this DWR to FERC document, DWR was notifying FERC that only surface defects were found ("spalling", a form of surface erosion, and "delamination" a separation of upper layers). DWR's letter then noted that repairs were being scheduled with a construction contractor to which wording of a list of descriptions of various repair items included "injecting non-shrink grout into voids". This letter, as written, makes "voiding" seem as a minor side item in a generic "to-do" list. Only surface "spalling" and "delamination" were noted as the only points of significance in the FERC letter. So why, other than this minor singular "void" mention, that out of 20 years of FERC/DWR communications, in 3,525 documents, are there no communications that include any notification of "void", "voiding", or "voids" to FERC? How does this reconcile with a serious issue -to which the first BOC memorandum reveals- of pressurized underslab "washing" (piping) linked with erosion voids "that were discovered and repaired in the past"? Why did DWR keep this significant "voiding" issue from FERC?

"Eventually, large voids can form beneath the chute slab that raise the possibility of structural collapse. [14]" -

What the BOC revealed is that the spillway was a prime threat to a blowout failure from a hydraulic lifting effect called Stagnation Pressure [13]. In "Predicting Spillway Failure" [14], underslab erosion and catastrophic structural failure are linked to the exact conditions outlined by the BOC's memorandum. Quoting the study: "Typically, damage resulting from hydrodynamic uplift on slabs (jacking) begins at the joints, where offsets or spalling has occurred. Spillway flows over these offsets can introduce water into the foundation, which can lead to structural damage as a result of either uplift or erosion of the foundation material. If this problem persists, there can be complete failure and removal of chute slabs. Structural collapse due to undermining of the chute slabs has been a difficult problem to evaluate due to lack of applicable data or analyses. This problem is generally more of a concern for structures where the chute and underdrain systems may be in poor condition due to aging or improper design. This problem is especially critical for chutes that are founded on soil because joint/crack flow can lead to erosion and undermining of the chute foundation and structural collapse of a chute slab." "Eventually, large voids can form beneath the chute slab that raise the possibility of structural collapse."

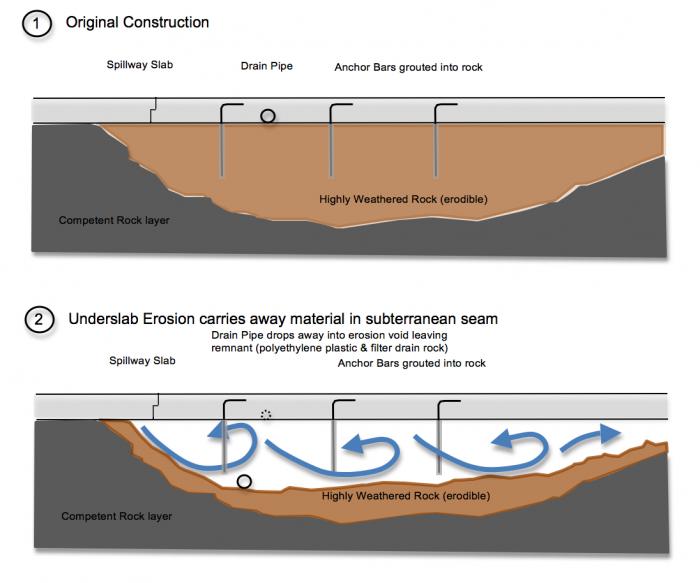

If DWR was aware that very large and deep voids were forming under the spillway concrete slabs, this article description could be lifted and placed word-for-word in what may be the summary for Oroville's Forensic Team's analysis report. In fact, the initial Oroville Forensic Team's report buttresses the volatility of the significant erosion risk of the main spillway's foundation in describing the foundation material as "soil-like" and "erodible material beneath the slab" with a "lack of foundation bond with concrete" [2]. The Team's findings continue with further notations of "Insufficient anchorage" which included installation in "weak foundation material" as potential failure contributors. How could DWR not anticipate this issue as a serious threat? (see Figs 1, 2, 3).

With the recent discovery & evidence of the 9+ foot thick Large "Void Fill" Block at the end of the spillway [15] and with the combined findings of the BOC and the Forensic Team's memorandum, this may result in the perfect storm for DWR. How? The Forensic team validates the "soil-like" volatility in erosion capacity of the foundation (Fig 1); the physical evidence of the vast erosion channels of the failed main spillway; the pile of Large Slab Blocks that collapsed just from above the initial blowout failure hole (void filling - see Fig 2); and then the BOC reveals that "voiding" was known in the past and that "voiding repairs" were performed in the past.

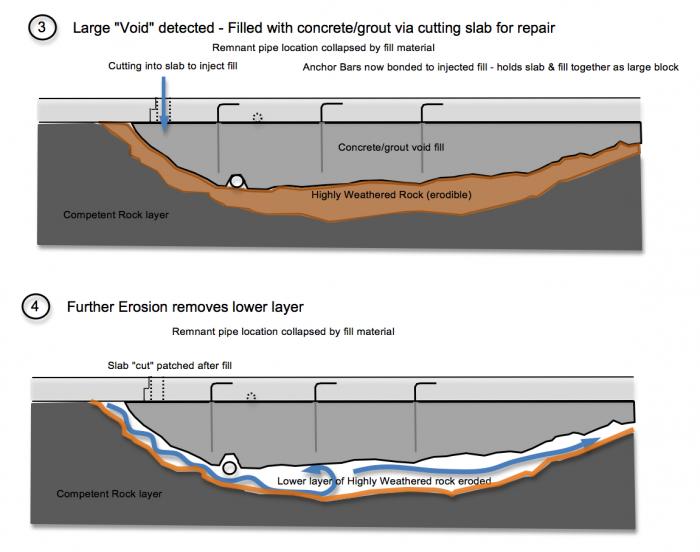

The combined evidence points to a "known" massive "void filling" activity that most likely "entombed" the anchor bars making the slabs a perfect target for a catastrophic blowout structural collapse or hydraulic lift blowout (see Fig 3). How would this be a perfect storm for DWR? Legal Liability in the "Standard of Care" cannot exempt the engineering decisions or lack of foreknowledge of this significant and near assuredly swift and catastrophic failure mode that was waiting to happen. Simply, "Void filling" to the degree of virtually removing the structural anchorage of the spillway slab + void is the worst possible condition a spillway slab could face. It simply is the worst possible Potential Failure Mode that any spillway design engineer could fathom. Structural Collapse, Hydraulic Jacking, Cavitation erosion, Slumping, Loss of Anchorage, all combine into the serious blowout result failure possibilities.

The FERC database evidences that DWR did not reveal this extremely serious issue to FERC [19]. The database also reveals that no serious PFM was submitted in the FERC Dam Safety and Surveillance Monitoring Reports (DSSMR's) nor in the Dam Safety Performance Monitoring Program regarding void, voiding, or voids. Unless the FERC database missed some hidden discussion, FERC was literally kept in the dark. It was DWR's responsibility to notify FERC immediately of a serious failure condition such as significant underslab voiding (i.e. "void filling" to the degree that the Large Slabs and Large Block evidence substantiates).

As FERC is a Federal agency charged with assuring the public safety in high hazard dams in where they work in cooperation with dam owners, and if DWR was complicit in either believing these "voids" were not a problem -or worse withheld the information- the net effect could be that a Federal agency was directly misled.

This issue now affects FEMA. If DWR misled one Federal agency, FERC, what is FEMA's position? FEMA has the discretion to deny funding due to "maintenance issues" not directly related to the "event". In 2015, in Polk County Arkansas, FEMA originally denied funding for a bridge replacement as the bridge collapse had known maintenance deficiencies [16]. Ultimately, FEMA reversed their decision on an appeal as the bridge was exposed to a flood disaster. However, in the case of Oroville's spillway, there was no excessive flow condition that could be considered a "disaster". The main spillway was operating at 55,000 cfs. The spillway was designed for a maximum structural capacity flow of 296,000 cfs. The outcome may be: FERC was misled; FEMA was attributing input from FERC; there was huge "voiding" that is the worst possible failure condition (non-addressed maintenance and a repairable precondition); and the spillway was operating within normal parameters (i.e. non-disaster flow rate).

FEMA may have no choice but to re-evaluate its funding reimbursement to DWR. FERC may have to investigate why DWR "dismissed the plausibility" of a failure of the concrete chute (Mark Anderson, acting DWR deputy director, ASCE May 21, 2017 statement) with such an egregious known failure mode to any competent spillway engineer. If FEMA doesn't investigate this serious potential precondition "known failure" issue, they may fall into the heated political cross-hairs from another appeal situation as FEMA has denied funding from the winter disaster that struck 10 counties in eastern Oregon in January 2017. Senators Ron Wyden, Jeff Merkley, and Rep. Greg Walden from Oregon are "seeking FEMA transparency" after FEMA's recent funding denial. Oregon is facing $17 million in damages from the winter storms in 10 counties. In contrast, DWR is planning on $500+ million in total reimbursement funding for the spillway repairs and reconstruction.

DWR is already borrowing by using a line of credit of $500 million to pay immediate bills with the expectation of reimbursement [4]. As FEMA has not yet paid, in the 75% normal disaster assistance coverage percentage of the total costs, DWR had to cover expenses in the interim with this line of credit. The rest of the 25% of the costs of the repairs and reconstruction is expected to be from DWR's Water Customers that are the combined group of urban and agricultural contractors including the State Water Project (SWP) that cover the operations and maintenance for Oroville. Even if FEMA doesn't resolve or end up fully denying funding to DWR, the Water Customers may balk at reimbursements to an engineering liability issue with finger pointing back to DWR.

Would this issue of a potential "known" egregious failure mode of "large void filling" risk a legal battle? Who would end up paying the bills? Would any participating contractors involved with any "large void" fills be liable under the "Standard of Care" Legal application? Will CA try to sue the contractors?

Regardless of the 25% outcome, the American Public will likely become involved as they may need to be convinced to help California for the bulk of funding in fixing this disaster.

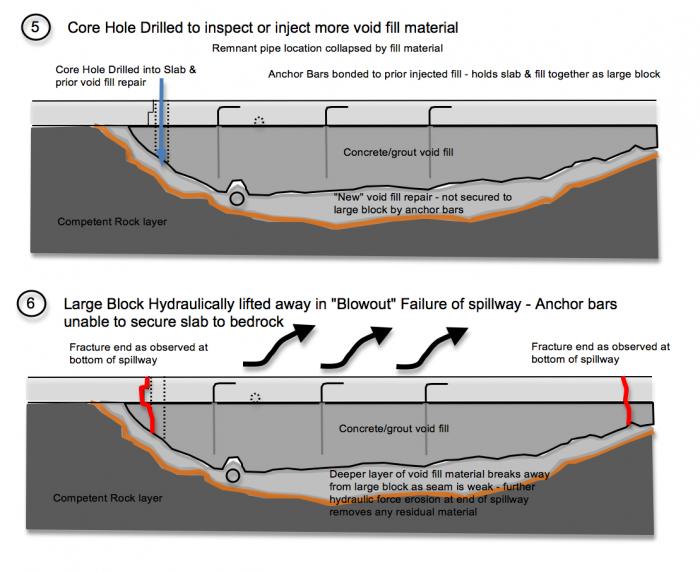

Fig 1. Evidence of the formation process of the Large Block "void fill". The original spillway was emplaced upon a channel of highly weathered rock. Anchor bars, with a 5 foot length extension below the spillway slab, were encased in grout from NX size drill holes into the substandard rock. The poor sealing design of the original spillway allowed volumes of pressurized waterflow to scour beneath the slabs from operation. Over time, this scouring eroded the highly weathered rock and created large voids under the slab. The slabs were thus acting like "bridges" over the voids. The risk to failure was great in these conditions as the anchorage from the anchor bars were greatly compromised, or even became completely isolated from rock by full "encasement" (See Fig 2).

Fig 2. Evidence of the formation process of the Large Block "void fill" - continued. DSOD inspectors identified "drummy patches" in a method of striking the top surface of the spillway concrete and then listening for the acoustic echo response. Some early methods to this technique is to use heavy chains to induce the vibratory acoustic stimulation. Other inspection methods use light tapping from hammers on the top surface. When a void area is detected, a process of repairing the void is to inject grout or a concrete material. However, this voiding was so significant in depth and volume that alarms should have been raised regarding the structural issue of the cause of the voiding (massive erosion in a large seam of highly frangible weathered rock). A fatal mistake occurs from the lack of recognition of this failure mode as DWR simply "fills in the massive void". The fatal mistake is that the anchor bars no longer have any structural (or greatly compromised) ability to secure the slab. The injected fill would entomb "all of" or nearly all of the ends of the protruding "anchor bars".

Fig 3. Evidence of the formation process of the Large Block "void fill" - continued. Further erosion under the first large void repair causes a new void that is deeper below the upper layer void fill concrete. Failure becomes inevitable as the slabs are at the mercy of "slumping", "hydraulic jacking", and "cavitation" failure modes. The Large Block was "lifted" up and moved down the spillway by powerful hydraulic forces during the blowout failure. Evidence suggests that this large "void fill" erosion problem could been in an area as wide as 80 feet and as long as 40 to 100 feet long (nearly 4 complete slab dimensions). The shear angle and force of breakage to the thickness of the Large Block indicates that a subsequent lift & fall "shock collision" of this block on other concrete caused the fracture.

References:

[1] Independent Board of Consultants (Board) Memorandum No. 1 for the Oroville Emergency Recovery - Spillways (Project), dated March 10, 2017 https://elibrary-backup.ferc.gov/IDMWS/search/fercadvsearch.asp 20170317-5113(32037979).pdf

"It seems likely that piping of foundation material beneath the chute slab may be responsible for the voids that have been found and repaired in the past."

[2] Oroville Dam Spillway Incident Forensic Investigation Team www.water.ca.gov/oroville-spillway/pdf/2017/Memorandum_050517.pdf

"16. Weathered rock and completely weathered rock that is soil-like material as slab foundation, without appropriate modification of the chute slab design, resulting in potentially erodible material beneath the slab and lack of foundation bond with concrete;"

"17. Less rigorous foundation preparation, resulting in lack of foundation bond with concrete."

"19. Insufficient anchorage, due to limited anchor development in the concrete, short anchor length, inadequate grouting or grout strength, and/or installation in weak foundation material."

[3] DWR/FERC letter - May 8 2009, https://elibrary-backup.ferc.gov/IDMWS/search/fercadvsearch.asp 20090519-0022(20870584).tif

"This is a follow up to Department of Water Resources (DWR) letters dated Aug 18, 2008, and October 16, 2008. DWR plans to conduct maintenance repairs to the Oroville Dam Spillway, Federal Energy Regulatory Commission (FERC) Project number 2100-CA. This letter provides a plan and a schedule for the work and is intended to supplement the previous letters. In April 2008, personnel from DWR's Division of Operations and Maintenance inspected Oroville Dam's spillway invert and walls for concrete deficiencies. While the overall condition of the spillway is good, the detailed visual and sounding inspection found areas of concrete spalling and delamination. DWR's Division of Engineering is preparting a construction contract for maintenance repairs that will cover approximately 7,000 square feet of the spillway. The scoped of the maintenance repair may include cutting, removing and replacing damage concrete, sand blasting exposed steel rebar, injecting non-shrink grout into voids, repairing or replacing joint seals as necessary, and placing epoxy adhesive to repair large cracks on the spillway surface."

[4] Oroville Dam: With bills rolling in, state borrows heavily, CA borrowing $500 million to pay for repair costs - expecting re-imbursement - The Sacramento Bee, May 8, 2017, - http://www.sacbee.com/news/local/article149363309.html

[5] Is "potential Oroville waiting to happen" at other spillways? The Sacramento Bee - May 21, 2017 http://www.sacbee.com/news/state/california/water-and-drought/article151889912.html

"Speaking at an American Society of Civil Engineers conference in Sacramento, Blackett listed the array of state and federal inspectors who visited Oroville Dam over the years. All of them, he said, missed signs that could have foreshadowed the gaping crater forming in the dam's concrete spillway in early February, eventually leading to the frantic evacuation of 188,000 people. One thing we (the inspectors) all have in common is that we didn't predict this happening," Blackett said."

"A California Department of Water Resources official on the same panel as Blackett also noted that inspections conducted over the years failed to predict the spillway failure."

"In 2014, an inspection actually dismissed the plausibility" of failures arising from erosion at the emergency spillway or a failure of the concrete chute" in the main spillway, said Mark Andersen, an acting DWR deputy director. So clearly ... we need to look institutionally at how we are doing these inspections and what we're learning from them," Andersen said."

[6] DSSMR's Dam Safety and Surveillance Monitoring Reports - Dam Safety Performance Monitoring Program - ferc.gov/industries/hydropower/safety/guidelines/dspmp/facilitators.asp

"December 4, 2002. As part of the Dam Safety Performance Monitoring Program (DSPMP), in cooperation with a team of dam owners and independent consultants, FERC developed guidance for carrying out a potential failure mode analysis (PFMA) as part of the FERC Part 12D Periodic Inspections by an Independent Consultant."

[7] FERC Dam Safety Program - 2008 - http://www.hydro.org/wp-content/uploads/2011/01/FERC-Dam-Safety-Program-Peter-Valeri.pdf

"The owner or the owner's consultant, with assistance from the FERC project engineer, should record the PFMA session, including PFMs, the adverse and favorable factors, the probability of occurrence, i.e. the probability of the causation event occurring and the dam failing during the event, and the licensee's ability to detect and/or mitigate the development of the failure mode, risk reduction measures, and assumptions."

[8] American Society of Civil Engineers 5th Forensic Engineering Congress November 10 - 15, 2009, Testifying Regarding the â₏½Standard of Care", Joshua B. Kardon, PhD, Testifying Regarding the Standard Of Care.pdf

[9] An Instrument of Risk Management: The Law, ALARP, As Low As Reasonably Practical, Civil Law & Courts, Liability from injury, R. G. Bea, Risk and Civil Law-2.pdf

"Civil law has a primary objective of controlling risk as effectively as possible: As Low As Reasonably Practicable (ALARP). Courts have defined two fundamental principles of decision making to internalize costs to create incentives to reduce risk levels as much as practicable. 1. If injury could have been practicably prevented, liability will be placed on that part in the relatively better position to prevent it. 2. If injury could not have been practicably prevented, liability is placed on party in the relatively better position to spread the risks of the injury. The civil law concept is to create incentives to invest in risk reduction rather than to pay damages for unprevented injuries. In risk control, the main tests applied are: is the risk so great or the outcome so unacceptable that is must be refused altogether or; is the risk so small that no further precaution is necessary or; if the risk falls between these two levels, then has it been reduced to a level which is ALARP"

[10] FERC Potential Failure Modes, PMFs, https://www.ferc.gov/industries/hydropower/safety/initiatives/pfms.asp

[11] DSOD Jan 12, 2000, Inspection Report - "Mr. Wolf said that an inspection of the spillway chute was made in the fall and he found some drummy patches. No treatment is proposed until they are damaged by a heavy flow."

[12] DSOD May 6, 2008, Inspection Report - "The chute floor was recently sounded with chain to look for delaminated areas. Suspect areas and visible defects were marked for future repairs."

[13] "VI-1. Stagnation Pressure Failure of Spillway Chutes" https://www.usbr.gov/ssle/damsafety/risk/BestPractices/Chapters/VI-1-20150610.pdf

[14] "Predicting Spillway Failure" Hydroworld.com http://www.hydroworld.com/articles/hr/print/volume-29/issue-7/articles/predicting-spillway-failure.html

"Typically, damage resulting from hydrodynamic uplift on slabs (jacking) begins at the joints, where offsets or spalling has occurred. Spillway flows over these offsets can introduce water into the foundation, which can lead to structural damage as a result of either uplift or erosion of the foundation material.

If this problem persists, there can be complete failure and removal of chute slabs. Structural collapse due to undermining of the chute slabs has been a difficult problem to evaluate due to lack of applicable data or analyses. This problem is generally more of a concern for structures where the chute and underdrain systems may be in poor condition due to aging or improper design. This problem is especially critical for chutes that are founded on soil because joint/crack flow can lead to erosion and undermining of the chute foundation and structural collapse of a chute slab."

[15] Catholic Online - Evidence of a 9+ foot thick Large Block of concrete at the bottom of the Main Spillway? Large Void Chasms under Spillway? DSOD Inspectors told not to fix until damaged? https://www.catholic.org/news/green/story.php?id=75023

[16] Ellison Wins Appeal to FEMA http://mypulsenews.com/ellison-wins-appeal-to-fema-2/

"FEMA determined the failure of the bridge is directly attributed to deferred maintenance noted on the bridge report instead of being â₏½a direct result of the declared event."

[17] Ore. lawmakers seek FEMA 'transparency' after funding denial - May 19, 2017 - http://www.ktvz.com/news/ore-lawmakers-seek-fema-transparency-after-funding-denial/507274830

"WASHINGTON - Sens. Ron Wyden and Jeff Merkley, both D-Ore., and Rep. Greg Walden, R-Ore., pushed the Federal Emergency Management Agency on Friday to be more transparent when it comes to the agency's process for granting federal disaster declarations. The lawmakers' push follows FEMA's denial of Oregon's request for a federal disaster declaration that would bring much-needed relief to communities hit by severe winter weather in January." "On March 9, Oregon Governor Kate Brown requested a federal disaster declaration for 10 Oregon counties, including Baker, Columbia, Curry, Deschutes Hood River, Josephine, Malheur, Multnomah, Union and Washington. The lawmakers wrote in support of the state's request on March 16. Brown announced the state would appeal the disaster declaration denial."

[18] General Specifications - max rated spillway operation 296,000 cfs. Levee restricted operation 150,000 cfs. Blowout failure occurred at 55,000 cfs.

[19] https://elibrary-backup.ferc.gov/IDMWS/search/fercadvsearch.asp docket P-2100 000 + keyword search

---

'Help Give every Student and Teacher FREE resources for a world-class Moral Catholic Education'

Copyright 2021 - Distributed by Catholic Online

Join the Movement

When you sign up below, you don't just join an email list - you're joining an entire movement for Free world class Catholic education.

Our Important Lenten Message - Please Watch

- Easter / Lent

- 5 Lenten Prayers

- Ash Wednesday

- 7 Morning Prayers

- Mysteries of the Rosary

- Litany of the Bl. Virgin Mary

- Popular Saints

- Popular Prayers

- Female Saints

- Saint Feast Days by Month

- Stations of the Cross

- St. Francis of Assisi

- St. Michael the Archangel

- The Apostles' Creed

- Unfailing Prayer to St. Anthony

- Pray the Rosary

![]()

Copyright 2026 Catholic Online. All materials contained on this site, whether written, audible or visual are the exclusive property of Catholic Online and are protected under U.S. and International copyright laws, © Copyright 2026 Catholic Online. Any unauthorized use, without prior written consent of Catholic Online is strictly forbidden and prohibited.

Catholic Online is a Project of Your Catholic Voice Foundation, a Not-for-Profit Corporation. Your Catholic Voice Foundation has been granted a recognition of tax exemption under Section 501(c)(3) of the Internal Revenue Code. Federal Tax Identification Number: 81-0596847. Your gift is tax-deductible as allowed by law.