Oroville Dam Leaking? 50yr Proof of 'through the dam' leakage? Will the dam breach?

FREE Catholic Classes

Oroville dam's "twin" green massive wet areas reveals notable leakage in its early operation. What was the water source to these huge "twin" wet areas? Contrary to DWR's recent assertions, historical information and internal construction stages from 1964 to 1967 may reveal the real details of how Leaks propagate, then seal, within Oroville dam. Since the threatening left abutment leak hasn't sealed, it should add further concern to the long persistent "Leaking" in the dam. How much internal erosion has occurred? What's the "piping" risk? Will it breach?

Hi readers, it seems you use Catholic Online a lot; that's great! It's a little awkward to ask, but we need your help. If you have already donated, we sincerely thank you. We're not salespeople, but we depend on donations averaging $14.76 and fewer than 1% of readers give. If you donate just $5.00, the price of your coffee, Catholic Online School could keep thriving. Thank you. Help Now >

Hi readers, it seems you use Catholic Online a lot; that's great! It's a little awkward to ask, but we need your help. If you have already donated, we sincerely thank you. We're not salespeople, but we depend on donations averaging $14.76 and fewer than 1% of readers give. If you donate just $5.00, the price of your coffee, Catholic Online School could keep thriving. Thank you. Help Now >

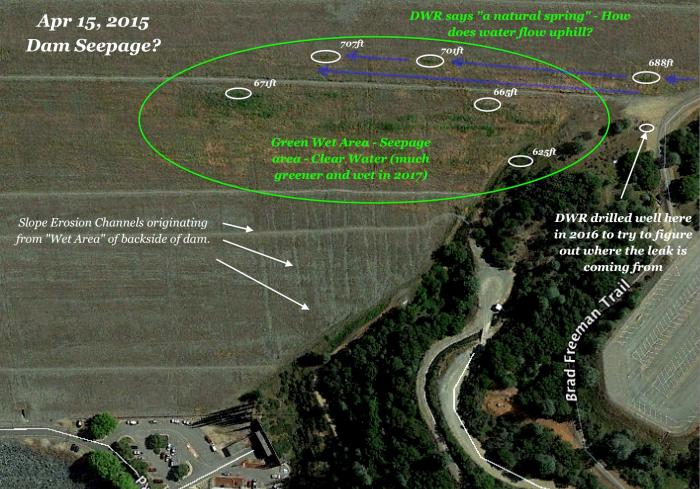

The green spots on the face of Oroville Dam are clearly visible in this aerial photo.

Highlights

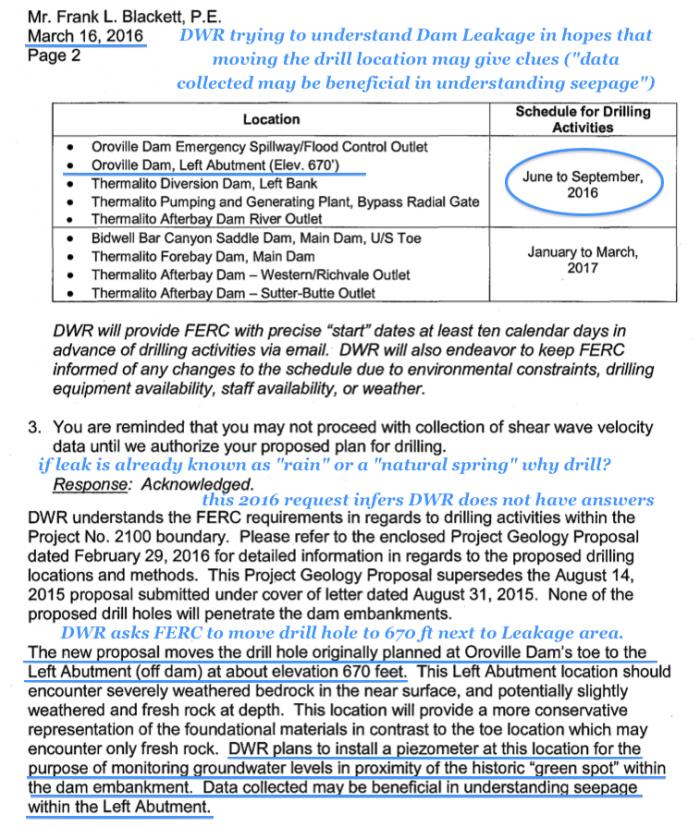

LOS ANGELES, CA (California Network) - Oroville Dam may be facing a breach danger from a serious and a dangerous form of a slow motion failure mode of the left abutment of the dam [3]. Recently, authorities to the dam have responded to the public stating "its a natural spring", or "the green spot is from rain". Yet, outside of a public forum, DWR asked the Federal Energy Regulatory Commission (FERC) to move a test drill well near the leakage to try to get answers in 2016. If it's known to be a harmless "natural spring" or from "rain" why drill? Why hasn't DWR publicly announced that they have a "test well" near the leakage area, which they noted to FERC, quote "data collected may be beneficial in understanding seepage"?[1] However, DWR's recent town hall meeting's answers, by DWR engineers and representatives, do not stand up to honest engineering scrutiny. The public deserves an honest technical risk assessment of this known dam failure mode threat [9].

Analysis of DWR's town hall answers reveals conflicts in engineering fluid flow hydraulics. The OrovilleMR News [2] reported "'The green spot is from rain, said Christy Jones, deputy director of statewide emergency preparedness and security for DWR.' - 'When the rain falls, the grass grows. There is no leak in the dam,' she said."

If the cause was from "rain", then downhill erosion channels should be uniform above, below, and along the face of the dam. Yet it is not. The notable downhill erosion channels originate exclusively at the Green Wet Area (See Fig 2). This answer implies that rainfall somehow concentrates at the Green Wet Area. DWR's answer, inferring that the wispy greening of the rest of the dam means that the intense and much larger growth of the vegetation in the Green Wet Area is from the same "rain fall" - is not supportable. Only a concentration of an internal source of a particular volume of water leakage at the Green Wet Area would support the visible downhill erosion channels.

Another DWR public town hall statement, from a DWR engineer, was "it's a natural spring" - i.e. causing the Green Wet Area. Yet, precise elevation markings of the near perfect horizontal progression of the Green Wet Area, away from the dam hillside abutment, defies this explanation. In fact, the horizontal elevation of the greening increases in elevation further away from the abutment (See Fig 2). Water does not flow uphill. If there were to be a natural spring, emitting water from within the left abutment hillside, there would be a downward curvature to any greening that would follow the hillside topography. It does not.

So why are reputable DWR engineers and representatives giving answers that are easily refuted? Worse, these answers infer a demonstration of a lack of engineering competency. Yet, these provably "flawed" engineering answers are the basis of reassuring the public that "There is no leak in the dam". With such a magnitude of risk from a known & dangerous dam failure mechanism, how can representatives state to concerned public citizens, of a certainty of "there is no leak in the dam" when they give flawed answers?

Oroville dam has proven that substantial leakage through the dam occurred, in a short period, in its early use. However, the dam is internally designed to "seal" leakage paths from the vertical Zone 2 fill layers. Silts and sands within this "Transition Zone" layer are designed to protect the central clay-clayey core water seal of the dam center. When the reservoir was initially filled and the dam started to slowly compact in a normal "settlement", there was an early period where a unique form of "differential settlement" caused twin column areas, in the center of the dam, to substantially leak. As this waterflow penetrated the clay-clayey Zone 1 core of the dam, the Zone 2 protection layers migrated silts and sands to "plug" and seal these leaking areas. After further slow compaction, the "differential settlement" in the center of the dam area balanced out and the seepage of these column areas remain healthy & sealed today. What caused this initial widespread dam leakage?

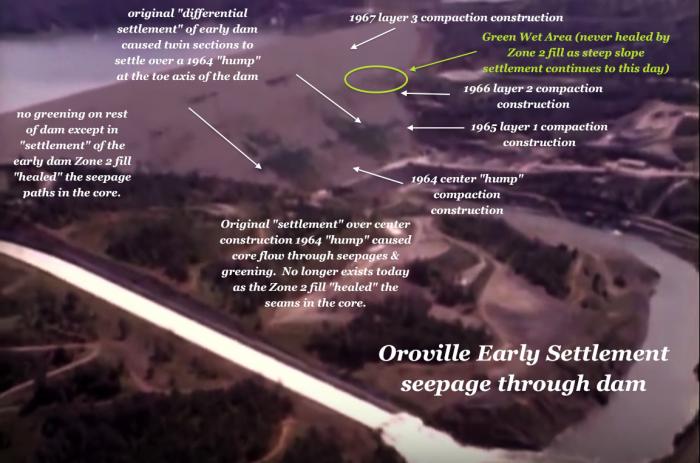

The answer to this original leakage is revealed in the construction stages from 1964 to 1967 of this massive earth fill dam. Due to the original canyon blasting, excavation, and core trench formation, the earth fill construction process, in the bottom of the dam, required leaving open access roads along the Feather River lower elevation hillsides. To keep on schedule, the 1964 Zone 3 fill layer was initially placed as a curved shaped "hump" along the toe axis of the dam, thus leaving the access roads open (See Fig 3). It wasn't until 1965 that the first massive 22 million cubic yards of the first main layer of the dam was filled in "on top of" the 1964 "hump". By then, all of the hillside access roads were not needed in that the core trench foundation, blasting, excavation, and grouting were complete.

Seasonal rains between these years of stages in construction became a very important factor to how Oroville Dam behaves today. Rainfall has the ability to percolate deep within a pervious material, even if compacted initially. When water penetrates a large volume of material, that is also under the gravitational force of "settlement", then the water is compacted and slowly forced out by settlement, a phenomenon of a denser compaction via consolidation occurs. Oroville dam was so massive that the constant ferrying of trainloads and relocatable conveyor belt systems required the construction to build the dam in large sectional layers. The conveyor belt systems were repositioned in pre-planned hillside slope locations to facilitate the next big large sectional layer. There are essentially 4 critical layers that come into play on this seasonal "consolidation compaction effect". First, in 1964, the "hump" at the bottom toe axis of the dam between the canyon walls, then in 1965 the leveled off layer of 22 million cubic yards of material as "horizontal layer 1", then in 1966 the leveled off layer of another 22 million cubic yards of material as "horizontal layer 2", and finally, in 1967 the finish layer of 19 million cubic yards of material to the crest as "layer 3".

At each stage of leveling off of layers of the "central toe hump", layer 1, layer 2, and layer 3, there was a sloping crest to the horizontal surface to prevent "pooling" of water from seasonal rains. Thus, this formed the gentle slopes of these layer seams that increase in elevation to a crest point as it moves away from the canyon abutments. The "central toe hump" layer had its own curvature so that it was protected from seasonal rain "pooling". The end result was that there were 4 sloping layers that had a surface compaction unique to the top layer of exposed seasonal rains in the series of years in the construction. This net effect has resulted in a "flow" preference at the seams by water via any leakage or seepage that migrates to these layered sections, both internal and external to the dam. This exact mechanism guides the same elevation slope of the Green Wet Area today as it is a defining characteristic to the same sloping curvature of the layer 2 to layer 3 boundary seam.

Thus the original substantial leakage through Oroville dam, in its early use, was from the upper layers settling over the first "central toe hump" layer emplaced in 1964. This caused a "differential settlement" stress on the core whereby substantial leakage occurred from the core of the dam and downward around both straddling sides of the bottom hump settling forces. It formed a perfectly symmetrical "differential settlement" stress leakage in a twin column stress shear back to the core. (See Fig 4). Thus, very large "twin" leakage patches of green, with lateral sloping horizontal greening along the layer seams, reveals these layered construction features. The twin columns and twin large greening patches are identical in nature all of the way up to the top layer (layer 3) with matching twin leakage seams. Critically, both the left and right abutments also had a "differential settlement" leakage in the layer 2 to layer 3 boundary area. In time, the twin column "differential settlement" leakage and the right abutment "differential settlement" leakage had stabilized and sealed itself within the core by the designed nature of the Zone 2 silts and sands flowing into shear induced defects and re-plugging the core.

However, the left abutment leakage has never sealed itself. This means that the continued "differential settlement" of the sharp slope transition of the left abutment has not been able to be protected by the Zone 2 design. Thus, the continued flow of leakage infers the existence of a long standing problem of a "differential settlement" issue through water flowing through the core of the dam. The reason why the Green Wet Area in this leakage is horizontal in nature and is at a mid-slope area of the outside shell of the dam is due to the prior construction layer consolidation compaction that has formed a degree of a phreatic shelf (waterflow shelf). This "waterflow shelf" likely has been augmented by silts and sands migration from the backside Zone 2 layer via the core leakage flows while "clogging" the Drain Zone in the process.

We ask you, humbly: don't scroll away.

Hi readers, it seems you use Catholic Online a lot; that's great! It's a little awkward to ask, but we need your help. If you have already donated, we sincerely thank you. We're not salespeople, but we depend on donations averaging $14.76 and fewer than 1% of readers give. If you donate just $5.00, the price of your coffee, Catholic Online School could keep thriving. Thank you.Help Now >

In other earthen dams, any core water penetration would follow a sharp downward curvature to the toe of the dam, internal to the dam fill and drainage zones, and would not be seen in the mid-slope area of the dam (called a phreatic line or curve). But, due to Oroville's massive size, requiring the numerous years of seasonal periods in layered construction & consolidation surfaces, unique characteristics have been inadvertently developed into the dam. This would escape a typically applied earthen dam behavior analysis. But Oroville dam is not normal due to its massive size and its required unique multi-year "layered" construction. To fully understand its behavior, engineers must look to the historic past in the myriad of construction images and understand these critical effect details - such as the layering structure, the seasonal rain consolidation effects, and the sharp slope left abutment ridge all the way back to the junction of the "core trench". Without understanding these interrelationship complexities, an engineer may never fully come to "true answers" today.

These unique construction characteristic "outcomes" may be at the root of why engineers are unable to correctly understand the clues and the nature of the "Historic Green Spot". Perhaps now, with the dam in a crisis mode of persistent threatening high reservoir water levels, should engineers seek to give the public true answers that survive the scrutiny of engineering fluid flow hydraulics. Indeed, hundreds of thousands of residents will be listening for these "new" answers.

Note: text markups, underlines, arrows, on images and documents for illustrative purposes and are not part of the originals. Elevation references in photos from WGS84 instead of Mean Sea Level.

Fig 1. DWR/FERC communications: DWR trying to understand Dam Leakage in hopes that moving a test drill location near the Wet Area may give answers. This recent 2016 test well infers that DWR is still seeking answers to the Leakage.

Fig 2. 2015 image of vegetation following an upward elevation slope away from the left abutment. Erosion channels, Greenage locations, non-greenage above & below & up the embankment, uphill waterflow, contradicts against a left abutment spring. Image courtesy of Google Earth.

Fig 3. The Sharp hillside slope of the future "left abutment" reveals the "differential settlement" failure mode to earthen dams. The steep slope goes straight back to the junction of the core of the future dam. Image reveals the 1964 Hump fill layer emplacement & access roads in the hillside.

Fig 4. Oroville dam's 1964 to 1967 layered construction led to "twin" green massive wet areas from leakage through the core of the dam in its early operation. Caused by "differential settlement", the dam core resealed itself from the Zone 2 silts and sands. However, the left abutment Leakage has never fully sealed for 50 years.

We ask you, humbly: don't scroll away.

Hi readers, it seems you use Catholic Online a lot; that's great! It's a little awkward to ask, but we need your help. If you have already donated, we sincerely thank you. We're not salespeople, but we depend on donations averaging $14.76 and fewer than 1% of readers give. If you donate just $5.00, the price of your coffee, Catholic Online School could keep thriving. Thank you.Help Now >

More Reading:

[1] Submittal: 20160316-5083, Date: 03/16/2016, Docket P-2100-000 - https://elibrary-backup.ferc.gov/IDMWS/search/advResults.asp - Department of Water Resources submits Plan and Schedule for Shear Wave Velocity Data Collection at Oroville, Bidwell Bar Canyon Saddle, Thermalito Diversion, Thermalito Forebay, and Thermalito Afterbay Dams under P-2100. 20160316-5083(31313837).pdf, page 2- "DWR plans to install a piezometer at this location for the purpose of monitoring groundwater levels in proximity of the historic "green spot" within the dam embankment. Data collected may be beneficial in understanding seepage within the Left Abutment."

[2] "Questions, answers and a bit of scorn for DWR at Oroville meeting" - Chico-Enterprise Record, Heather Hacking, - http://www.orovillemr.com/article/NB/20170502/NEWS/170509947

[3] Oroville Dam Breach? DWR Investigating Leaking - Hasn't Revealed this to the Public - https://www.catholic.org/news/green/story.php?id=74661

[4] Teton Dam disaster - 1976 Teton Dam Collapse - https://ioem.idaho.gov/Pages/History/DamCollapse.aspx

[5] Time: "Teton: Eyewitness to Disaster" http://content.time.com/time/magazine/article/0,9171,918216,00.html

[6] Oroville Dam - Tallest in the United States - https://en.wikipedia.org/wiki/Oroville_Dam

[7] Design and Construction of Embankment Dams - Differential Settlement Failure/Cracking Fig 2.4(a) sharp abutment change - http://aitech.ac.jp/~narita/tembankmentdam1.pdf

[8] Embankment Dams-Design Standards No. 13 - Longitudinal Cracking from Differential Settlement pg 5 - http://www.damsafety.org/media/Documents/DownloadableDocuments/ResourcesByTopic/DS13-11.pdf

[9] Lessons Learned from Dam Incidents and Failures - Steep rock abutments leading to "differential settlement, cracking, and failure by internal erosion - http://damfailures.org/wp-content/uploads/2015/07/Lessons-Learned-Complete-List.pdf

---

'Help Give every Student and Teacher FREE resources for a world-class Moral Catholic Education'

Copyright 2021 - Distributed by Catholic Online

Daily Readings for Friday, April 19, 2024

Daily Readings for Friday, April 19, 2024 St. Alphege: Saint of the Day for Friday, April 19, 2024

St. Alphege: Saint of the Day for Friday, April 19, 2024 Stewardship Prayer: Prayer of the Day for Friday, April 19, 2024

Stewardship Prayer: Prayer of the Day for Friday, April 19, 2024